The Hidden Chemistry of Emissions

“I’ve been out in the field, catching pneumonia on a hard winter’s night in offshore Norway—that’s how I learned the value of good data.”

After describing his real education, John-Arne Stokkan, Quorum’s Energy Components Product Manager, has established the fact that managing production means managing chemical reactions and those reactions create emissions. Just as chemistry drives production performance, data drives emissions performance.

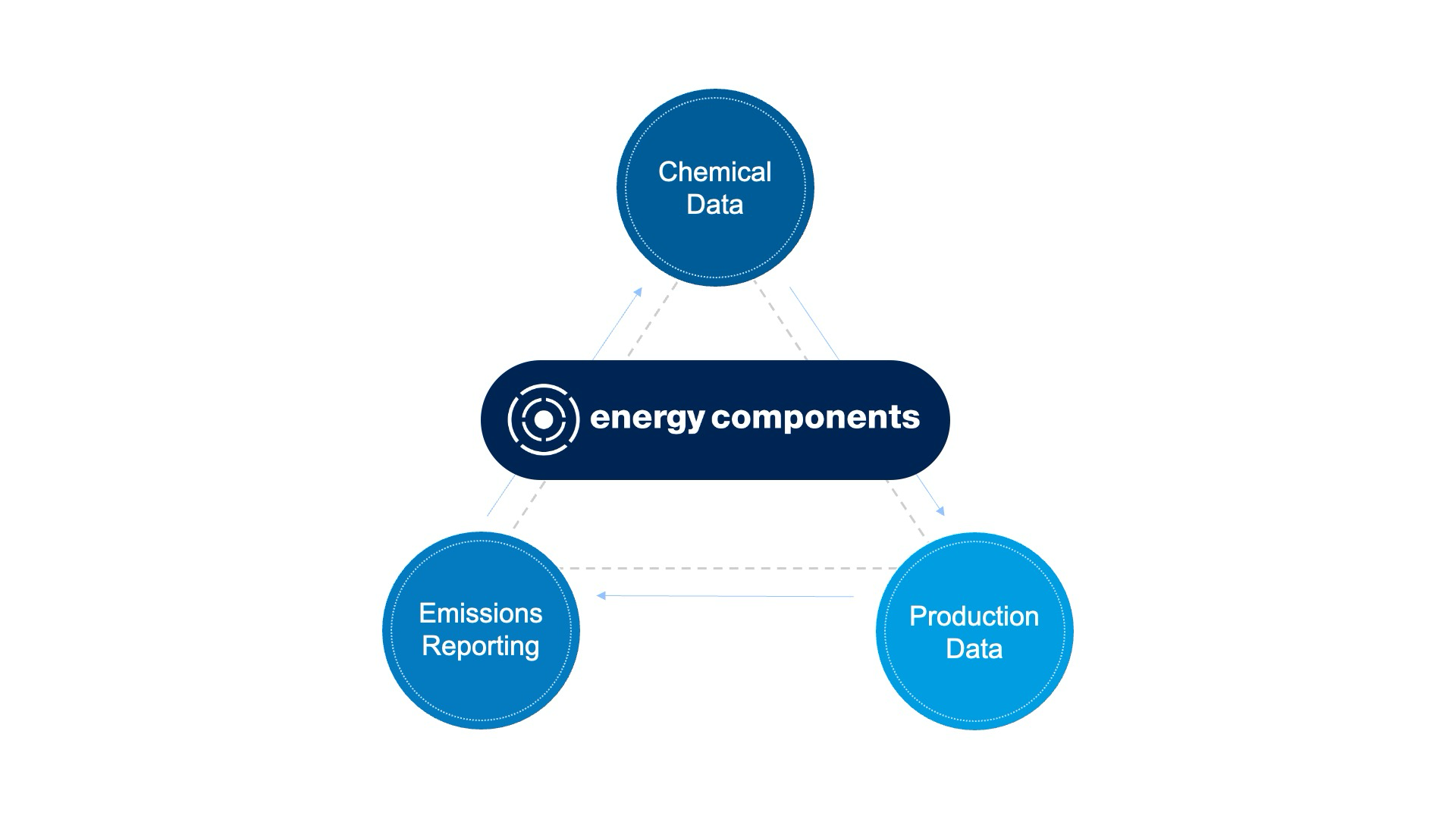

Quorum’s Energy Components (EC) brings these together, uniting chemical and emissions management under one integrated system that captures, connects, and contextualizes data for every stage of operations.

The Challenge: Disconnected Data, Rising Costs

Across the energy industry, emissions data often lives in spreadsheets, manual reports, or isolated historians—scattered and reactive rather than actionable. Without an integrated view, small inconsistencies can lead to big consequences: over-reporting, under-estimating, or delayed decisions that impact both performance and profit. As John-Arne puts it, “Too much time is spent chasing spreadsheets when we could be optimizing.”

Operators face mounting pressure to reduce emissions while staying profitable. But with disconnected systems, even the best-intentioned teams lose valuable time reconciling data instead of improving it. The message is clear: data fragmentation creates operational risk, and that risk carries a cost.

The Solution: Energy Components as the Data Orchestrator

Energy Components serves as the backbone for automated, traceable, and integrated emissions management. Acting as the data orchestrator, Energy Components collects, validates, and connects information across production volumes, chemical usage, and emissions sources, transforming complexity into clarity.

Energy Components sits in the middle as the orchestrator of your data—it collects, validates, and connects everything. This orchestration delivers traceability and automation at scale, allowing operators to monitor real-time emissions alongside production and treatment data. The result is a holistic view of performance, one that links environmental outcomes directly to operational efficiency.

Because emissions management isn’t an isolated task: it’s a continuous part of production optimization, chemical efficiency, and sustainability goals.

Turning Data into Decisions

Every barrel of oil has a chemical cost, and every drop of efficiency counts. Energy Components helps operators quantify both.

With Energy Components, upstream teams can:

- Calculate emissions accurately in alignment with regulatory frameworks.

- Reduce manual effort and reporting time through automated data flows.

- Model reduction strategies and carbon cost scenarios with precision.

This integrated visibility means fewer shutdowns, optimized treatment programs, and better tracking of emissions intensity per BOE—turning compliance data into actionable insight.

When accurate data drives decisions, operators gain measurable value in cost efficiency, sustainability performance, and operational agility.

Efficiency Meets Environmental Stewardship

In modern energy operations, efficiency and environmental stewardship share the same foundation: information. The chemistry behind production and the data behind emissions are connected by purpose—to optimize, sustain, and improve.

Better information means better dosage, better performance, and fewer surprises. When emissions data is just as accessible and governed as production data, companies can refine strategies, reduce waste, and strengthen ESG performance. Better visibility leads to cleaner operations and stronger accountability across the value chain.

From Field to Future

Better information doesn’t start in the boardroom; it starts in the field where weather, equipment, and chemical performance all test the limits of human endurance. That’s where the importance of reliable, automated data truly comes into focus.

What once depended on notebooks and manual readings now happens through automation and integration. The same chemistry that once challenged field crews is now tracked, optimized, and analyzed through Energy Components, turning every data point into a decision.

By uniting chemistry, production, and emissions data under one governed system, Energy Components connects field experience with digital intelligence ensuring every insight is traceable, auditable, and actionable.

When data tells the full story, from the tank to the atmosphere, operators can act faster, cleaner, and smarter. That’s the promise of Energy Components.

Ready to jumpstart your emissions compliance? Watch this webinar with John-Arne or request a demo to start today.

Previous Page

Previous Page